Pyrometers / Hot Metal Detectors

Infrared switches (also called hot metal detectors) record the temperature just like an infrared thermometer, but do not output a temperature, but a switching signal when a certain temperature is exceeded or not reached.

Categories

-

CAPELLA C322 (Portable 2-Color Pyrometer)

3 temp. ranges betw. 300 and 1800°C / 572 and 3272°F

Spectral range 1.45 – 1.8 µm; <1 ms fast;

Smallest spot size 1.2 mm; 0.4 mm with close-up lens

Display, adjustment keys, USB -

CAPELLA C311 (Portable 2-Color Pyrometer)

3 temp. ranges betw. 600 and 2500°C / 1112 and 4532°F;

Spectral range 0.75–1.1 µm; <1 ms fast;

Smallest spot size 1.2 mm; 0.4 mm with close-up lens

Display, adjustment keys, USB -

CAPELLA C318 (Portable 1-Color Pyrometer)

1 temp. range from 180 to 1300°C / 356 to 2372°F;

Spectral range 1.65 – 2.1 µm; <1 ms fast;

Smallest spot size 1.2 mm; 0.4 mm with close-up lens

Display, adjustment keys, USB -

CAPELLA C316 (Portable 1-Color Pyrometer)

3 temp. ranges betw. 250 and 2500°C / 482 and 4532°F;

Spectral range 1.45 – 1.8 µm; <1 ms fast;

Smallest spot size 1.2 mm; 0.4 mm with close-up lens

Display, adjustment keys, USB -

CAPELLA C309 (Portable 1-Color Pyrometer)

5 temp. ranges betw. 550 and 3300°C / 1022 and 5972°F;

Spectral range 0.7–1.1 µm; <1 ms fast;

Smallest spot size 1.2 mm; 0.4 mm with close-up lens

Display, adjustment keys, USB -

METIS M322 (2-Color Pyrometer)

7 temp. ranges between 300 and 3300°C / 572 and 5972°F

Spectral range 1.45 – 1.8 µm; <1 ms fast;

Smallest spot size 0.8 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M311 (2-Color Pyrometer)

7 temp. ranges betw. 600 and 3300°C / 1112 and 5972°F

Spectral range 0.75 – 1.1 µm; <1 ms fast;

Smallest spot size 0.8 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M323 (1-Color Pyrometer)

3 temp.ranges betw. 50 and 1500°C / 122 and 2732°F

Spectral range 2 – 2.6 µm; <1 ms fast;

Smallest spot size 0.6 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M318 (1-Color Pyrometer)

3 temp.ranges betw. 100 and 1300°C / 212 and 2372°F

Spectral range 1.65 – 2.1 µm; <1 ms fast;

Smallest spot size 0.4 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M316 (1-Color Pyrometer)

5 Messbereiche zw. 200 und 3300°C / 392 und 5972°F

Spektralbereich 1,45 – 1,8 µm; < 1 ms schnell

Smallest spot size 0.4 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M309 (1-Color Pyrometer)

6 temp. ranges between 550 and 3300°C / 1022 and 5972°F;

Spectral range 0.7 – 1.1 µm; <1 ms fast;

Smallest spot size 0.4 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M313 (1-Color Pyrometer)

5 temp. ranges betw. 400 and 3800°C / 752 and 6872°F

Spectral range 1.27 µm; <1 ms fast;

Smallest spot size 0.3 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M308 (1-Color Pyrometer)

2 temp. ranges betw. 600 and 1800°C / 1112 and 3272°F

Spectral range 0.88 µm; <1 ms fast;

Smallest spot size 0.7 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M306 (1-Color Pyrometer)

Temp. range 900 – 2500°C / 1652 – 4532°F

Spectral range 0.6 µm; <1 ms fast;

Smallest spot size 1.3 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS M3F1 (Flame Pyrometer)

4 temp. ranges between 600 and 3300°C / 1112 and 5972°F

Spektralbereich 0,695 – 1,1 µm; 10 ms schnell

Display, adjustm. buttons, switching inputs / outputs -

METIS H322 (High-Speed 2-Color Pyrometer)

8 temp. ranges betw. 350 and 3000°C / 662 and 5432°F

Spectral range 1.45 – 1.8 µm; < 80 µs fast;

Smallest spot size 0.8 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS H311 (High-Speed 2-Color Pyrometer)

7 temp. ranges betw. 600 and 3300°C / 1112 and 5972°F

Spectral range 0.75 – 1.1 µm; < 80 µs fast;

Smallest spot size 0.8 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS H318 (High-Speed 1-Color Pyrometer)

2 temp. ranges betw. 120 and 800°C / 248 and 1472°F

Spectral range 1.65 – 2.1 µm; < 40 µs fast;

Smallest spot size 0.4 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS H316 (High-Speed 1-Color Pyrometer)

7 temp. ranges betw. 250 and 2500°C / 482 and 4532°F;

Spectral range 1.45 – 1.8 µm; < 40 µs fast;

Smallest spot size 0.4 mm

Display, adjustm. buttons, switching inputs / outputs -

METIS H309 (High-Speed 1-Color Pyrometer)

5 temp. ranges betw. 550 and 2000°C / 1022 and 3632°F

Spectral range 0.7 – 1.1 µm; < 40 µs fast;

Smallest spot size 0.4 mm

Display, adjustm. buttons, switching inputs / outputs -

Heavy-Duty Measuring System for METIS M3 or H3 Pyrometers

Focus distance up to 4.5 m

Use up to 250°C on the measuring head

Stainless steel braided hose in lengths up to 30 m

Air purge for the optics system -

SIRIUS SI23 (1-Color Pyrometer)

3 temp.ranges betw. 50 and 900°C / 122 and 1652°F

Spectral range 2 – 2.6 µm; 5 ms fast;

Smallest spot size 1.3 mm

Peak picker, laser targeting light button -

SIRIUS SI18 (1-Color Pyrometer)

2 temp.ranges betw. 100 and 850°C / 212 and 1562°F

Spectral range 1.65 – 2.1 µm; 5 ms fast;

Smallest spot size 1.3 mm

Peak picker, laser targeting light button -

SIRIUS SI16 (1-Color Pyrometer)

3 temp. ranges betw. 250 and 1800°C / 482 and 3272°F;

Spectral range 1.45 – 1.8 µm; 5 ms fast;

Smallest spot size 1.3 mm

Peak picker, laser targeting light button -

SIRIUS SS09 (1-Color Pyrometer)

2 temp. ranges between 550 and 1800°C / 1022 and 3272°F;

Spectral range 0.7 – 1.1 µm; 5 ms fast;

Smallest spot size 1.3 mm

Peak picker, laser targeting light button -

POLARIS PI16 (IR Switch / Hot Metal Detector)

3 switching ranges between 250 and 1800°C / 482 and 3272°F

Spektralbereich 1,45 – 1,8 µm; 4 ms schnell

Smallest spot size 1.3 mm

Laser targeting light button -

POLARIS PS09 (IR Switch / Hot Metal Detector)

2 switching ranges between 550 and 1800°C / 1022 and 3272°F

Spectral range 0.7 – 1.1 µm; 4 ms fast;

Smallest spot size 1.3 mm

Laser targeting light button -

DIADEM DI16 (Transfer Standard Pyrometer)

for verifying and pyrometric readjustment of the CS1500

2 temp.ranges betw. 250 and 1500°C / 482 and 2732°F

Spectral range 1.45 – 1.8 µm; 5 ms fast;

Display -

DIADEM DS09 (Transfer Standard Pyrometer)

2 temp. ranges betw. 600 and 1800°C

Spectral range 0.7 – 1.1 µm; 5 ms fast;

Smallest spot size 1.1 mm

Display -

DIADEM DS06 (Transfer Standard Pyrometer)

Temp. range 900 – 3000°C

Spectral range 0.65 µm; 5 ms fast;

Smallest spot size 1 mm

Display -

DIADEM DI13 (Transfer Standard Pyrometer)

Temp. range 1000 – 3500°C

Spectral range 1.27 µm; 5 ms fast;

Smallest spot size 1 mm

Display -

METIS MB39 (1-Color Pyrometer)

2 temp. ranges between 150 and 2500°C;

Spectral range 3.95 µm, 3 ms fast

Smallest spot size 0.7 mm

Switching input to clear the peak picker

Series

Find out more in our ![]() Product overview about pyrometers, calibration sources, software and Accessories as well as helpful selection criteria and our services.

Product overview about pyrometers, calibration sources, software and Accessories as well as helpful selection criteria and our services.

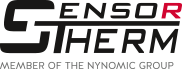

All Sensortherm infrared thermometers are optimized for industrial applications. In addition to robust aluminum or stainless steel housings, optimized optical components with high optical resolution are used so that measurements can still be made with small spot sizes even at larger distances from the measuring object. A digital signal processing ensures extremely precise measurement results.

The correct selection of a pyrometer depends on many factors. In case of doubt, let us advise you before you decide for a device, we have possible solutions that cannot be obtained through simple product filtering.

FAQ

What are pyrometers with digital signal processing?

For operation with changing ambient temperatures and process parameters, all pyrometers require mathematical operations to calculate the correct temperature.

This applies in particular to the quotient formation in 2-color pyrometers, the multiplication for the emissivity adjustment and compensation of the temperature coefficients as well as the summation for the correction of gain-dependent offset currents.

In contrast to analog processing, the use of fully digital signal processing of the influencing variables in Sensortherm pyrometers ensures 100% reproducibility of the displayed measured values because digital numbers are processed here and no more or less flawed analog signals.

In contrast to analog processing, the use of fully digital signal processing of the influencing variables in Sensortherm pyrometers ensures 100% reproducibility of the displayed measured values because digital numbers are processed here and no more or less flawed analog signals.

In particular, temperature and age-related deviations are thereby avoided and ensures the transferability from device to device.

What are the special features of Sensortherm pyrometers?

![]() Pyrometers with an integrated temperature controller and output of manipulated variables are used to maintain setpoint values, e.g. in additive printing processes or heating processes.

Pyrometers with an integrated temperature controller and output of manipulated variables are used to maintain setpoint values, e.g. in additive printing processes or heating processes.

![]() Pyrometers together with a PID program controller enable the targeted programming of time-controlled heating ramps, holding times or cooling rates, e.g. during heating processes.

Pyrometers together with a PID program controller enable the targeted programming of time-controlled heating ramps, holding times or cooling rates, e.g. during heating processes.

![]() High-speed pyrometers are used for very fast measuring processes. Devices with an integrated PID temperature controller and manipulated variable output monitor processes and control the laser power, e.g. in additive printing processes.

High-speed pyrometers are used for very fast measuring processes. Devices with an integrated PID temperature controller and manipulated variable output monitor processes and control the laser power, e.g. in additive printing processes.

![]() Pyrometers with a temperature line scanner record 16 measuring regions for separate evaluation of temperature profiles as well as min., max. and average values.

Pyrometers with a temperature line scanner record 16 measuring regions for separate evaluation of temperature profiles as well as min., max. and average values.

![]() METIS M3 and H3 pyrometers are equipped with several inputs for external pyrometer control as well as switching outputs for signal output in the event of temperature events.

METIS M3 and H3 pyrometers are equipped with several inputs for external pyrometer control as well as switching outputs for signal output in the event of temperature events.

![]() Ultra-precise Transfer Standard Pyrometers are traced back to ITS90 and are used for checking and adjusting calibration sources. They are also used for comparison measurements with other pyrometers to check their accuracy or to adjust them directly with the reference values.

Ultra-precise Transfer Standard Pyrometers are traced back to ITS90 and are used for checking and adjusting calibration sources. They are also used for comparison measurements with other pyrometers to check their accuracy or to adjust them directly with the reference values.

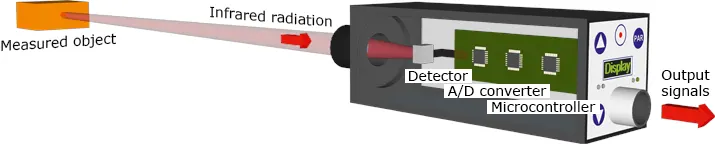

How do the pyrometer series differ?

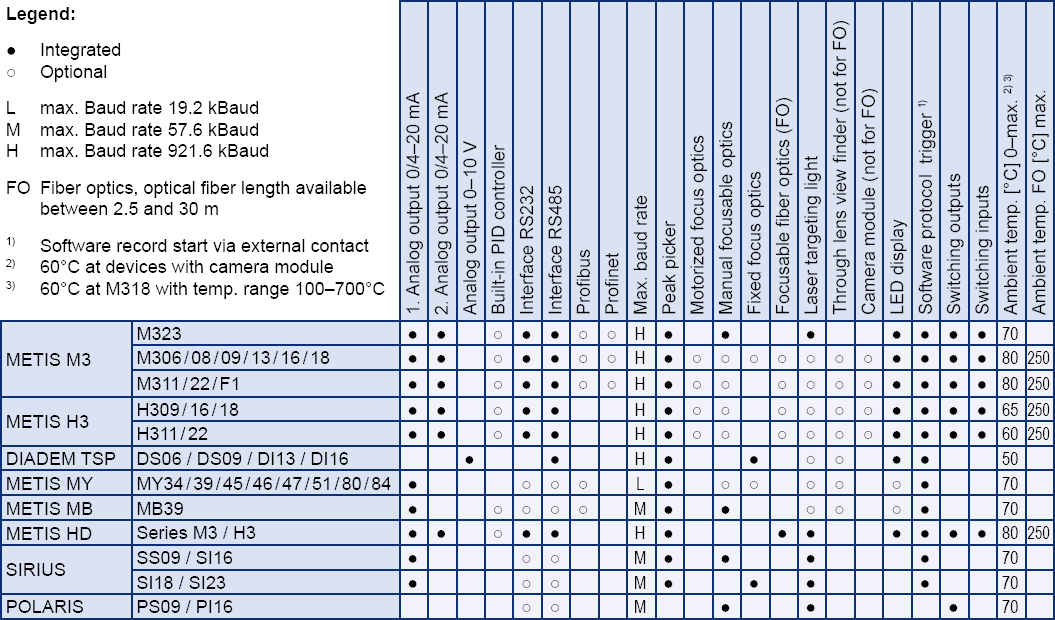

Which spectral range should I choose?

Pyrometers / infrared switches measure in different spectral ranges, the selection depends on the material to be measured:

![]()

Short-wave spectral ranges are mostly used to measure metals, ceramics, composite materials, glass melt, graphite or flames. In the case of metal measurements, a spectral range as short as possible is advantageous for an accurate measurement. For technical reasons, however, these only start at slightly higher measuring ranges, so that a model with a slightly longer-wave spectral range may have to be selected. To compensate for these inaccuracies, all devices have an adjustable emissivity, used ofr compensation of these differences.

Short-wave spectral ranges are mostly used to measure metals, ceramics, composite materials, glass melt, graphite or flames. In the case of metal measurements, a spectral range as short as possible is advantageous for an accurate measurement. For technical reasons, however, these only start at slightly higher measuring ranges, so that a model with a slightly longer-wave spectral range may have to be selected. To compensate for these inaccuracies, all devices have an adjustable emissivity, used ofr compensation of these differences.

![]() Longer-wave spectral ranges are used to measure non-metals, flue gas, gas flames, semiconductors, wafers or glass surfaces. The spectral ranges have been found by material analysis to be suitable for each purpose. The area of application is explained for the respective pyrometer models, but we would also be happy to advise you.

Longer-wave spectral ranges are used to measure non-metals, flue gas, gas flames, semiconductors, wafers or glass surfaces. The spectral ranges have been found by material analysis to be suitable for each purpose. The area of application is explained for the respective pyrometer models, but we would also be happy to advise you.

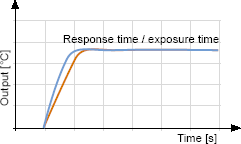

What is the measurement speed or response time or exposure time?

For all Sensortherm pyrometers the response time t90 is specified. It indicates the time that the pyrometer needs to reach 90% signal height of a 100% temperature step event. Within the response time two measurements and the complete signal processing will be performed, so the exposure time is twice as high. The shorter the response time of a pyrometer, the faster a measured value is provided to the output. This is particularly important when measuring parts move quickly or when using a scanner or if the pyrometer’s measuring value should be used to further system control.

For all Sensortherm pyrometers the response time t90 is specified. It indicates the time that the pyrometer needs to reach 90% signal height of a 100% temperature step event. Within the response time two measurements and the complete signal processing will be performed, so the exposure time is twice as high. The shorter the response time of a pyrometer, the faster a measured value is provided to the output. This is particularly important when measuring parts move quickly or when using a scanner or if the pyrometer’s measuring value should be used to further system control.

Do I need a 1-color pyrometer or a 2-color pyrometer?

With 1-color pyrometers (standard infrared thermometers) most measuring object temperatures can be determined very well. Only the emissivity of the material to be measured needs to be taken into account during the measurement, but for most materials it is largely known and can be read out from tables. Measurement errors are extremely small with such devices.

With 1-color pyrometers (standard infrared thermometers) most measuring object temperatures can be determined very well. Only the emissivity of the material to be measured needs to be taken into account during the measurement, but for most materials it is largely known and can be read out from tables. Measurement errors are extremely small with such devices.

Measurement conditions:

- The measured object must always be larger than the pyrometer’s spot size, since the mean value of the radiation is detected via the spot size. If the measured object is smaller than the spot size diame-ter, measuring errors occur because background temperatures are included in the measurement.

- As an aid in alignment, the device can be aligned to maximum temperature.

- The pyrometer’s field of view must be free from fumes, smoke or dust. These lead to a signal weak-ening and thus to a lower indication of the temperature.

- Measurements through windows are possible if they have constant transmittance properties in the spectral range of the pyrometer. The transmittance losses must be entered into the pyrometer.

2-color pyrometers measure in two different spectral ranges simultaneously and determine the temperature from the ratio of the two radiation intensities. With 2-color pyrometers, it is not necessary to know the emissivity of the measurement material, it is canceled in the ratio formation.

2-color pyrometers measure in two different spectral ranges simultaneously and determine the temperature from the ratio of the two radiation intensities. With 2-color pyrometers, it is not necessary to know the emissivity of the measurement material, it is canceled in the ratio formation.

This allows measurements through dirty viewing windows or exposure to smoke or dust if the radiation ratio remains constant, i.e. a signal weakening has the same effect on both wavelength ranges.

Measurement conditions:

- If the measuring object is smaller than the pyrometer measuring field, a warm background temperature is included in the measurement. However, this only shows effects from approx. 300°C and above that the influence is only slight.

- If the target is smaller than the spot size diameter, a lower signal strength occurs. Safe measurement is possible up to a signal strength of 10%. If this value is not reached, the measurement is switched off and the display no longer displays any measured value.

- Aligning the device to maximum temperature, such as with radiation pyrometers, does not work here, but it can aligned to maximum signal strength.

- At the 2 wavelengths, it can occure that the object has different emissivities (for example at bare metal surfaces). In this case, the emissivity slope of the target must be considered and entered into the device.

- If the emissivity changes due to the surface or depending on the temperature for the two wavelengths (also, for example, at an oil film on the lens), large deviations of the 2-color temperature may result. A 2-color pyrometer behaves several times more sensitive to wavelength-dependent signal changes than a radiation pyrometer, the larger the difference and the lower the absolute value of the emissivity.

- Measurements through polluting viewing windows or through smoke or dust in the pyrometer’s field of view are possible because the radiation ratio remains constant in this case. Prerequisite: The signal attenuation is homogeneous on both wavelength ranges.

- For measurements through windows, the window material needs to be considered. If the transmission properties are not uniform (for example for quartz glass), the corresponding emissivity slope must be entered.

How do I best align the pyrometer to the measuring object?

![]() The laser targeting light shows a red for stationary devices and a green laser dot for handheld devices, which shows the center of the measuring field. In the focal distance of the lens, where the measuring field is smallest, the laser point is also smallest and sharpest.

The laser targeting light shows a red for stationary devices and a green laser dot for handheld devices, which shows the center of the measuring field. In the focal distance of the lens, where the measuring field is smallest, the laser point is also smallest and sharpest.

![]() The through-lens view finder is (right side) is mirror directly into the lens, so that the measuring object can be detected visually. A centering circle shows the measuring field, the measuring distance is found when the object is shown in focus.

The through-lens view finder is (right side) is mirror directly into the lens, so that the measuring object can be detected visually. A centering circle shows the measuring field, the measuring distance is found when the object is shown in focus.

![]() Pyrometers with a color camera module have their own video output for direct connection to a television or monitor. The pyrometer is aligned and focused over a target circle in the television picture.

With the automatic, highly dynamic image brightness adjustment, the camera module is also ideally suited for process monitoring.

Pyrometers with a color camera module have their own video output for direct connection to a television or monitor. The pyrometer is aligned and focused over a target circle in the television picture.

With the automatic, highly dynamic image brightness adjustment, the camera module is also ideally suited for process monitoring.

Optics

Manually adjustable optics are integrated in the pyrometer or designed as fiber optics. They are set to the required measuring distance or the focus distance by shifting the optics tube.

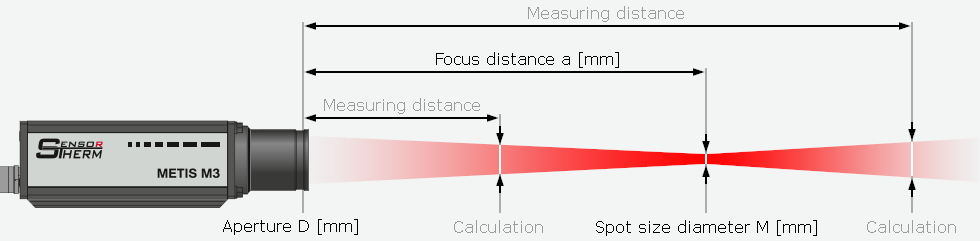

Manually adjustable optics are integrated in the pyrometer or designed as fiber optics. They are set to the required measuring distance or the focus distance by shifting the optics tube. Motorized focusable optics on METIS-M3 models are integrated in the pyrometer. The focus distance is displayed on the device and changed there or on the PC using the SensorTools software. The lens is then adjusted by a motor so that the smallest possible measuring field is achieved in the set focus distance.

Motorized focusable optics on METIS-M3 models are integrated in the pyrometer. The focus distance is displayed on the device and changed there or on the PC using the SensorTools software. The lens is then adjusted by a motor so that the smallest possible measuring field is achieved in the set focus distance. Fixed focus optics are set to a specific measurement or focus distance. Fixed focus optics in the METIS series are available with very small spot sizes with a distance ratio of up to 700:1, in the METIS M3 series up to 900:1.

Fixed focus optics are set to a specific measurement or focus distance. Fixed focus optics in the METIS series are available with very small spot sizes with a distance ratio of up to 700:1, in the METIS M3 series up to 900:1.

Can I measure outside of the focus distance?

Yes sure. The spot size diameter is smallest in the focal point of the optics (focus distance), but measurements in the defocused area (in front of or behind the focus) are also possible with the same accuracy, but the measuring area is usually larger.

Spot size calculation in front of or behind the focus distance

What options does the SensorTools software offer, included in the scope of delivery?

![]() SensorTools is a very extensive adjustment, communication, analysis and evaluation software that is included with all pyrometers, scanners, controllers, displays and calibration sources as standard.

SensorTools is a very extensive adjustment, communication, analysis and evaluation software that is included with all pyrometers, scanners, controllers, displays and calibration sources as standard.

More details can be found here.